FIUKA rolling technology – we ensure optimum results

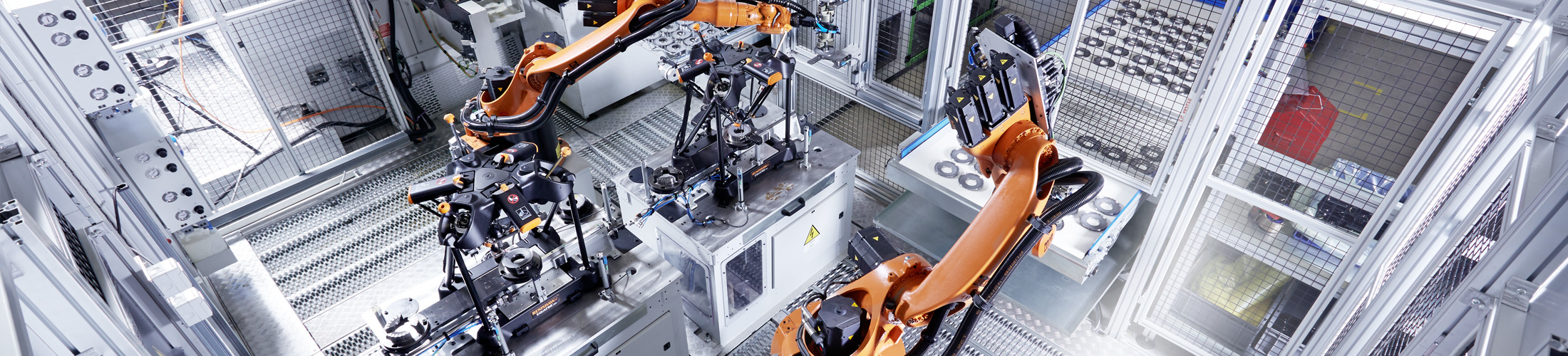

In the field of rolling technology, we at FIUKA rely on special machines manufactured especially for us and designed with us. FIUKA manufactures rotationally symmetrical components for a wide variety of applications, such as electrified and conventional powertrains, on fully automated rolling machines. Roller forming is suitable for the production of rotationally symmetrical components with different wall thicknesses and complex shapes, while maintaining high surface qualities. A wide range of steel grades and aluminum are used as materials.

Cost advantages for our customers

Roller forming technology offers advantages in many areas and has proven its value over other manufacturing processes. It is possible to produce poly-V profiles and sealing grooves, as well as to replace multi-part welded assemblies with single-part solutions. This minimizes potential defects and ensures a high standard of quality.

In transmission technology, sealings are frequently used. By using deep-drawn pistons with a rolled groove in the outer area, cost-effective rectangular or lip seals can be used.

In the segment of poly-V belt drives, roller forming is a cost-effective alternative to, for example, cast and machined pulleys. Here, we also use our in-house manufactured, deep-drawn blanks and feed them into an automated roller burnishing and turning process, additionally benefiting from the cold work hardening of the formed material.

Roller forming can be advantageous for all components where different material thicknesses are required. For example, balancing discs often have to be more solid on the outside, while thinner walls are sufficient on the inside. By roller forming, the use of material can be reduced and the workpiece is strengthened only in the areas actually required.

Our roller forming technology convinces by:

- Production of complicated geometries

- High cost efficiency due to better material utilization

- work hardening and high surface quality

The high vertical range of manufacture from the in-house produced deep-drawing blank to roller forming and the machining of certain functional areas as well as process-integrated measurement offers our customers not only quality advantages, but also the decisive cost advantage.